Split Polymer Labyrinth Seal (SPLS)

- Non-Contact Split Rotary Seal for Bearing Protection

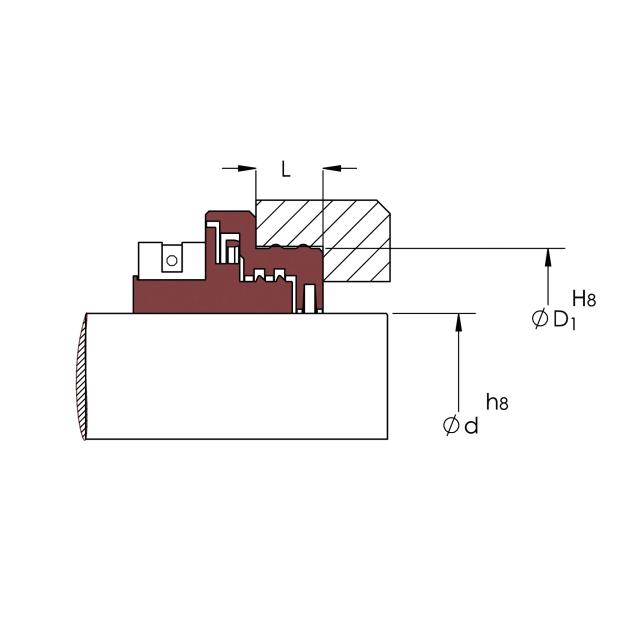

This SPLS uses Chesterton’s exclusive, industry-leading thermoset polymer to create a non- contact, three-piece seal design that includes a rotor with an integrated valve, a stator, and a metal clamp with no wearing parts.

Product Features

-

- A split, non-contact design that reduces installation time and minimizes downtime for critical equipment

- Reduces the chances of fretting caused by lip seals

- Keeps lubrication in and seals out external contamination

- Unitized design and durable material provide easy, reliable installation

- Available in a variety of configurations to meet plant-wide equipment needs

- Standard sizes available for popular equipment; custom sizes available upon request

- IP65 protection against water jets and dust

Technical Data

| Temperature Min | -60 °F ( -50 °C ) |

|---|---|

| Temperature Max | 185 °F ( 85 °C ) |

| Speed Max | 30.5 m/s ( 6000 fpm ) |

| Eccentricity | 0.75 mm ( 0.030 in ) |

Let's talk

For inquires about products, sales, or to request a quote, please contact our Sales Office.